iBOS® - Intelligent Battery Operating System

If you change batteries in your forklift truck, you need iBOS!

-

Get more performance from your batteries.

Get more performance from your batteries. - Reduce labor costs.

- Don't use more batteries and chargers than you need.

- Make your batteries last longer.

Cost effective battery room management made simple

Changing batteries on an electric

forklift truck can be a confusing, time consuming process that, when

done incorrectly, leads to drastically shortened battery run times

and battery life. The bigger the battery room the more confusing it

becomes and the more expensive the problems become. Almost all

non-managed battery rooms have more batteries than they need, do not

use their batteries correctly, and managers typically guess

at

the correct number of batteries to purchase. This all leads to

wasted money, time and effort.

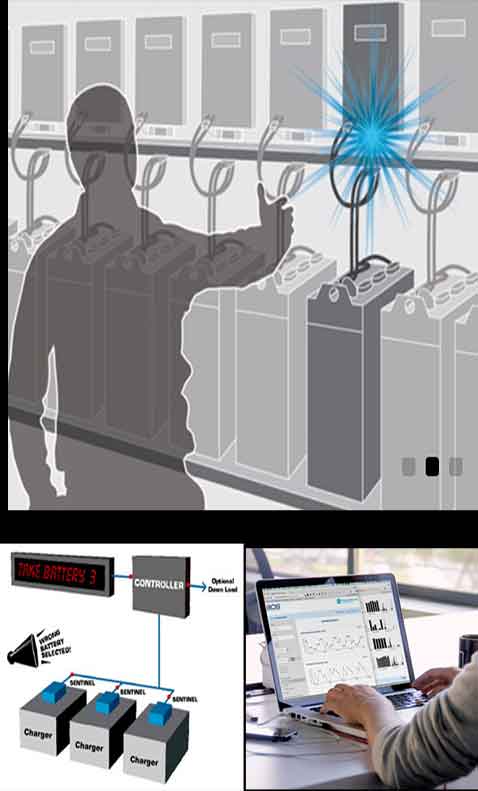

An iBOS system eliminates the guesswork and the worry involved with managing your battery room and saves you money while it does it. It enables a Lean approach to managing your battery room. iBOS is the most widely used battery management system and it allows distribution centers and warehouses to effectively operate with a two batteries to one forklift truck ratio.

How it Works

The system knows when the chargers finish

charging and a simple screen or pick light automatically tells the

operator exactly which charger to get their next battery from.

It is like a navigation system for your battery room!

An iBOS

system will bring you the following benefits:

-

Simplified and directed battery selection: This will make sure that all batteries are fully charged and properly cooled down. Operator judgment is eliminated.

-

Faster battery changes: Save 2 to 5 minutes per change.

-

Fewer battery changes: 30 minutes longer battery run time resulting in 10 to 20% fewer battery changes.

-

Longer battery life: 6 months additional life due to longer battery cool down. This leads to fewer battery purchases each year.

-

More accurate battery purchases: Right-size your battery fleet with information that saves tens of thousands of dollars per year.

-

Too many batteries: Wastes capital. This is a very typical situation in most non-managed battery rooms.

-

Too few batteries: Decreases productivity.

-

Greater battery room visibility: Identify non-working equipment and problems in the battery room via management reports.